|

|||||||

| PV, 120 (Amazon), 1800 General Forum for the Volvo PV, 120 and 1800 cars |

Information

Information

|

|

A bit more power from my B20.Views : 6525 Replies : 20Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

VOC member

Last Online: May 20th, 2024 16:41

Join Date: Jan 2008

Location: Sheffield

|

Wanting a bit more power from my B20, for road use only.Presently standard twin carb su,with electronic ignition.

4 branch manifold, simonz exhaust, flywheel lightened from standard 9.6Kg to 8.5Kg. I can have the valves bouncing at 4000 rpm.Presume my valve springs are the original ones and require replacing. Thinking of fitting a better cam. Machining and fitting a 44mm valved head which i currently have as a spare. Advise appreciated please, re cam profile, where to remove metal from the head, stronger valve springs, etc. With the above advise, my son can have the machining work done cheaply, ( don't forget i am a Yorkshireman ). Thanks in advance for your help. Chris. |

|

|

|

|

|

#2 |

|

Chief Bodger

Last Online: Today 13:47

Join Date: Oct 2009

Location: Aberdeen

|

I'm no expert but hopefully to get the thread rolling:

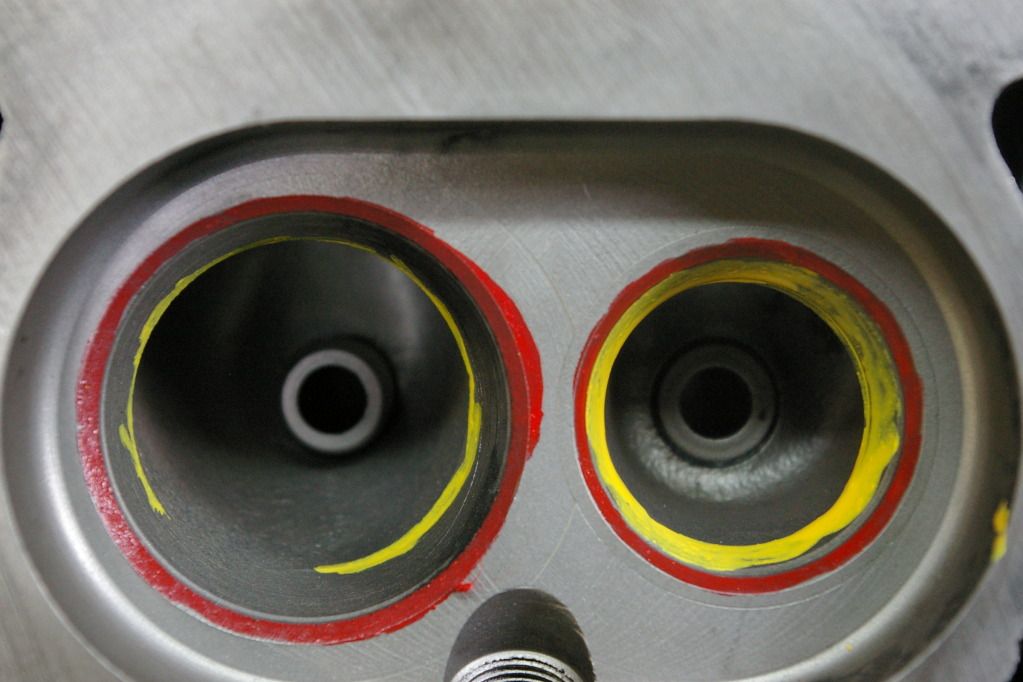

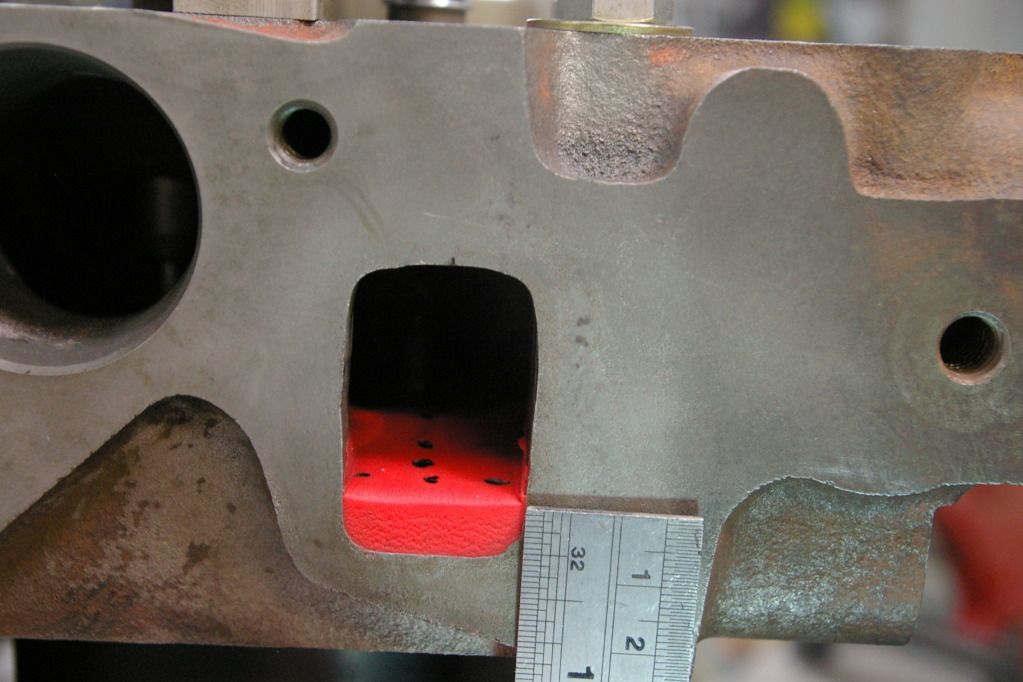

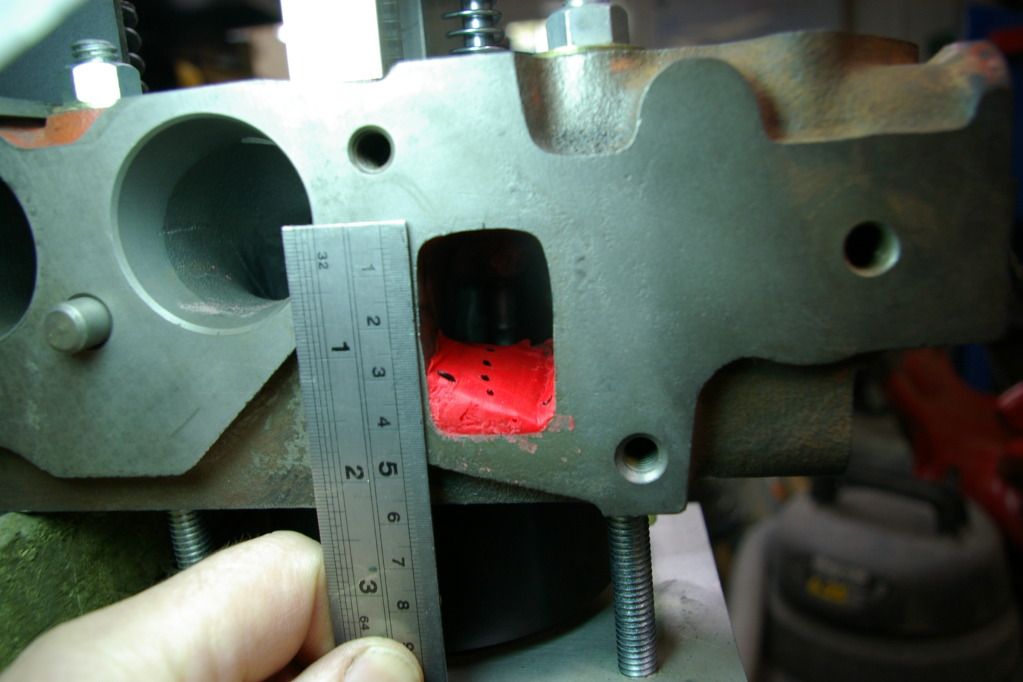

Some info from Canuck from turbo bricks: "The main issue for poor flow is the restriction behind the valve seat. It can be removed up to the seat without issue. Exhaust port - The exhaust port is too large, specifically the floor is too low, so don't go matching it to any gaskets or goofy stuff like that. It will only make things worse. What I do is blend the port back from behind the seat then widen it slightly towards the top, tapering on the way out." It's also recommended to deck the block to level with the top of the pistons. I thought standard springs should be fine and they were recommended for my KG10 cam from KG Trimning. Depending on how serious a cam you choose and how much headwork etc and how much you rev the engine I suppose should decide if you need stiffer springs or dual springs. Some more info from Canuck and attached some pics that he is talking about: "Probing both ports with the manometer verifies that funky things happen around the seat area as reading go from relatively stable to whacky (showing flow disturbances by the seat). I've posted photo's of these heads before - but this time I've highlighted the area I actually work on. I usually colour the valve seat red to stop me hitting it and the area in yellow is the restriction in the throat. It`s gotta go - so here we are at the start.  And this is a roughed in port bowl, nothing fancy here at all.  I've taken the back (side away from the port entry/exit) out to the seat as the majority of the intake flow is heading in that direction and the exhaust starts there.  I usually carve around the outside of the valve guide on the exhaust side and accentuate the port roof to complement the bias in the port.   Short-side radius on the intake is cleaned up and profiled, but I try not to make it larger.  Not much to say about the short-side radius on the exhaust side, I just smooth it out and try to keep it from getting sharp. Which may not be the right idea. Port alterations: Raised port floor (1/4")  Sloped port floor

|

|

|

|

| The Following 7 Users Say Thank You to Burdekin For This Useful Post: |

|

|

#3 |

|

Senior Member

Last Online: Jan 10th, 2024 20:21

Join Date: Nov 2010

Location: Columbus, OH

|

Mitch, so you have the KG10 cam installed? Do you like it and how would you describe the power range of the cam? I am trying to get Canuck to port a head for me, otherwise I may try it myself.

__________________

1959 Volvo Amazon. Chassis #17048 |

|

|

|

|

|

#4 |

|

Chief Bodger

Last Online: Today 13:47

Join Date: Oct 2009

Location: Aberdeen

|

Yeah I like it. The engine is still quite new and not fully run in so hasn't been driven hard. It pulls nicely from low revs and accelerates well, it's a good step up from the D and K cams.

It's now a much better engine than the engines that were in my P1800 and Amazon but maybe not a good comparison as they were both probably a little tired especially the Amazon engine which had been really poorly put back together. If Canuck is doing you a head he'll probably be able to guide you to a nice cam to match. I wanted my engine to be a nice mild street engine, about 145 to 150hp is my goal but as I haven't had it on a dyno so I don't know if it is there or not yet. Canuck's first engine that he did was 160hp and sounds quite nice with twin SUs and an R cam I think. Phil Singher is out your way as well so another good option for you and I think Phil also knows how to make a good B20 head. I've e-mailed him in the past and he's a nice helpful guy so even if you don't get the head done by him it would be worth asking Phil and Canuck for advice and as many pics as you can get. A basic port wouldn't be difficult but it's worth taking your time and understanding what works with a B20 and what doesn't and what makes them worse. Last edited by Burdekin; Dec 27th, 2012 at 07:24. |

|

|

|

| The Following User Says Thank You to Burdekin For This Useful Post: |

|

|

#5 |

|

Senior Member

Last Online: Jan 10th, 2024 20:21

Join Date: Nov 2010

Location: Columbus, OH

|

I am not trying to steal this thread, but a few things that I have found are that the head is key for performance. However most people that I have encountered only do B20 race heads and they want $2000 for a head. Phil only builds complete engines and not heads alone. I have a '75 B20F head already, but I don't want to mess it up, it already has the hardened exhaust seats.

I talked with KG trimning and they are able to do heads at the moment (1-2 month turn around) however shipping is too expensive. Complete heads with hardened seats were about $1400 w/o VAT. For a carb, I am going to run a Weber 38/38 dges downdraft, it actually flows better than some DCOE carbs. It has two power valves and a accelerator pump. I also found an R-Sport GT downdraft manifold. This should provide good power and gas mileage.

__________________

1959 Volvo Amazon. Chassis #17048 |

|

|

|

| The Following User Says Thank You to lukeball For This Useful Post: |

|

|

#6 |

|

Member

Last Online: Sep 6th, 2023 19:43

Join Date: Dec 2012

Location: Winnipeg, Manitoba, Canada

|

"Port alterations:

Raised port floor (1/4") Sloped port floor" What is the significance or a raised / sloped port floor. Are you adding or subtracting head material? P |

|

|

|

|

|

#7 |

|

Chief Bodger

Last Online: Today 13:47

Join Date: Oct 2009

Location: Aberdeen

|

This was Canuck experimenting. The port floor is too low and exhaust gases don't flow well because of it. He made it higher on one and sloped on another. I think Phil Singher builds his exhaust port floor up. If doing a DIY job it is common for the B20 to not touch the exhaust port floor as it makes it worse. I think the raised exhaust port floor also helps draw in intake gases.

Last edited by Burdekin; Dec 28th, 2012 at 08:50. |

|

|

|

|

|

#8 |

|

VOC Member

Last Online: Today 15:08

Join Date: Jul 2006

Location: Chatham

|

Apparently even Volvo raised the exhaust port floor on the very last series of B20 heads. Easy to do at the casting stage of course. AFAIK these heads were only on the B20 engines fitted to the 240 models, most of which went to the USA. No B20 240's sold in the UK. Improving the exhaust flow with the raised port floor probably helped with emissions enough to keep them happy until the OHC engine came on stream.

Some "tuners" say to increase the exhaust valve size by a couple of mm to improve things but this seems to me to be counter intuitive unless you have the later improved ports. Looking at the pictures of the head I was reminded that you have to visualise the port shapes based on the flow being in and out. Not so easy to see the inlet port shape when looking down from the combustion chamber. Unfortunately, smoothly shaped ports that look like a work of art aren't usually the most efficient. |

|

|

|

|

|

#9 |

|

Master Member

Last Online: Mar 14th, 2024 17:23

Join Date: Jun 2009

Location: Milton Keynes

|

Chris,

Have you decided what cam profile to go for? Are you going to lighten your flywheel further? Anythink else you are going for? |

|

|

|

|

|

#10 |

|

Senior Member

Last Online: Jan 10th, 2024 20:21

Join Date: Nov 2010

Location: Columbus, OH

|

I actually have the late B20F head from a 240. You can tell because "Volvo" is cast in a later and larger font on the top of the head. I didn't know that it had the raised port floor. Thank Derek.

I talked with Craig. I am going to use a Schneider 274F cam and he recommended 44mm intake 38mm exhaust with porting. With new stainless steel high-flow valves and other components, he quoted $1100. I am going with that. It should be nice. What are you running for compression?

__________________

1959 Volvo Amazon. Chassis #17048 |

|

|

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|