|

|||||||

| Performance Volvo Cars A forum for those interested in any Volvo performance car from any era, FWD, RWD and AWD! |

Information

Information

|

|

1968 US Estate Being Fitted with Vintage Performance PartsViews : 1854 Replies : 6Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Member

Last Online: Nov 11th, 2023 13:34

Join Date: Jul 2016

Location: Brattleboro, VT

|

Hello everyone, I am new here and am from the US and live in the State of Vermont in New England. Have had a number of 122s and 220's and a 1967 P1800s in the past. I waited for 35-years to purchase this three-owner 220 from a friend. It spent its life in inland Florida and Georgia (no rust) before coming up here to New England where it has only been used in the fair weather months and carefully stored over the winter. It will be used a shop car for my early auto restoration shop that is celebrating 40-years in business this summer and also a very active old car online magazine: TheOldMotor.com during the spring, summer, and fall. I have alway liked high-performance automobiles and since this is such a nice original car, it is not being altered in any way other by using bolt on performance parts that can easily removed to turn it back to a stock condition easily and quickly. Two of the early additions can be seen below: a Judson Supercharger that I am rebuilding for it and a Abarth exhaust system that is what we call in the US N.O.S. (new parts that were never installed on a car and have been in storage since being manufactured.) I will update this thread as often as I can and hope you enjoy it.  The Judson Blower above, and below the Abarth exhaust system.

|

|

|

|

|

|

#2 |

|

Member

Last Online: Nov 11th, 2023 13:34

Join Date: Jul 2016

Location: Brattleboro, VT

|

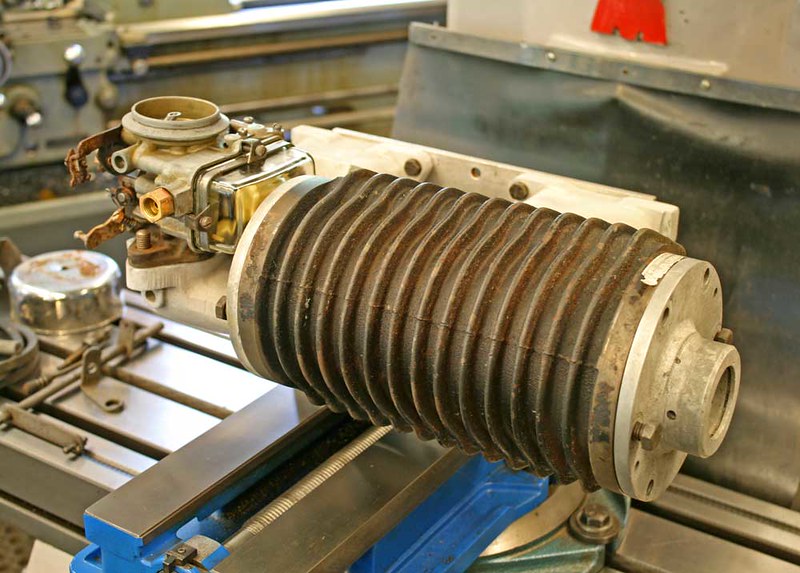

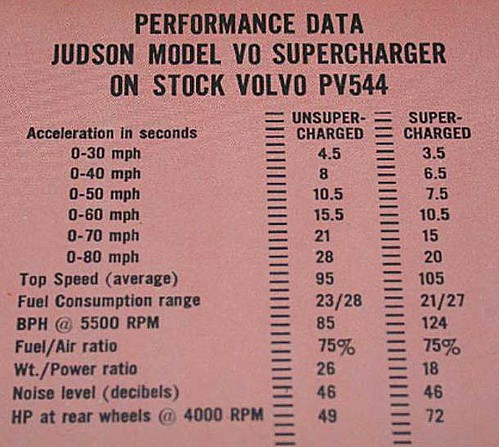

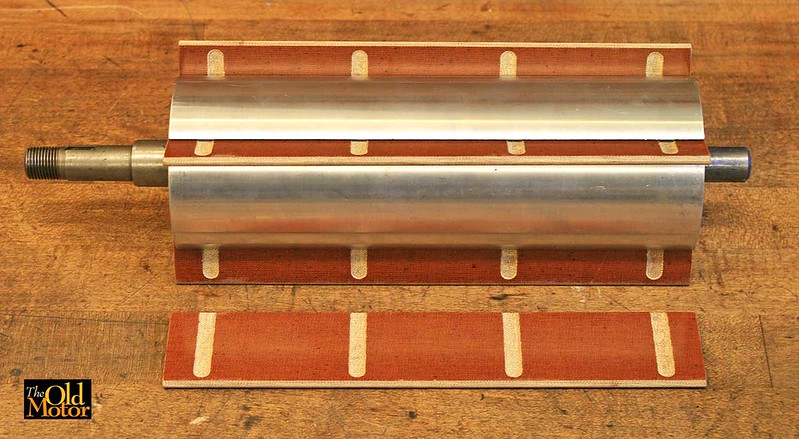

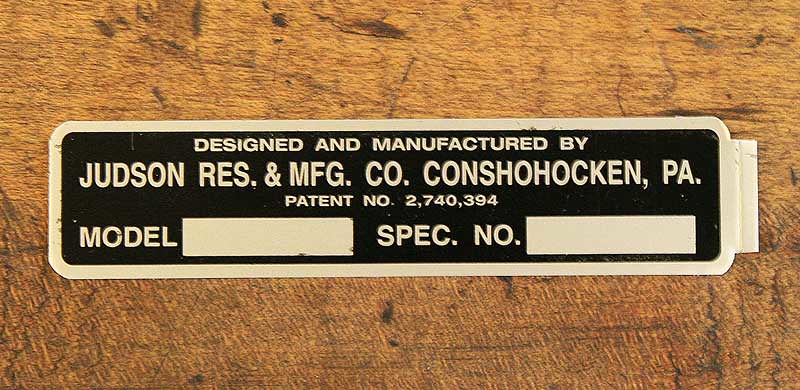

Wanting to use a few pieces of period-correct speed equipment on the 220 Station Wagon I bought a Judson Supercharger as can be seen above on a P1800. I had one in the past and was very satisfied with its performance which does not affect regular around town or highway driving at all. The blowers were also fitted to 544, 122s models. The Judson is an axial unit using sliding vanes of micarda in an aluminum rotor and are held against the inside of the cast iron housing by centrifugal force. The unit starts generating boost pressure as soon as the rpms pick up coming off of idle speed and peak at redline at about 7psi and adds at least 30% more power, bumping the original 115 hp. up to 149 hp. The vanes are made of reinforced micarda, a tough thermosetting plastic and cloth composite that is the same material used for Volvo "fiber" camshaft gears.  It utilizes four sliding vanes that are mounted at an angle to an aluminum rotor with an alloy steel shaft supported by ball bearings. The vanes themselves weigh half as much aluminum, but are less subject to heat expansion. The rotating assembly is lubricated by the gasoline and air mixture and Marvel Mystery Oil supplied by a Marvel Oiler as seen below. The supercharger drive ratio is 1 to 1.101 and it spins at 6055 rpm at redline.  In the 1950's and 60's the Judson Research and Manufacturing Company of Conshohocken, Pennsylvania made these vane type superchargers for Volkswagen, MG, Triumph, Volvo and other cars including the Mercedes 190SL. The blower bolts on and does not alter the rest of car in any way. The rebuilding process will be shared w/you here and on TheOldMotor.com The chart below shows the performance enhancement on an earlier 544.

|

|

|

|

| The Following 2 Users Say Thank You to Vintagewrench For This Useful Post: |

|

|

#3 |

|

Member

Last Online: Nov 11th, 2023 13:34

Join Date: Jul 2016

Location: Brattleboro, VT

|

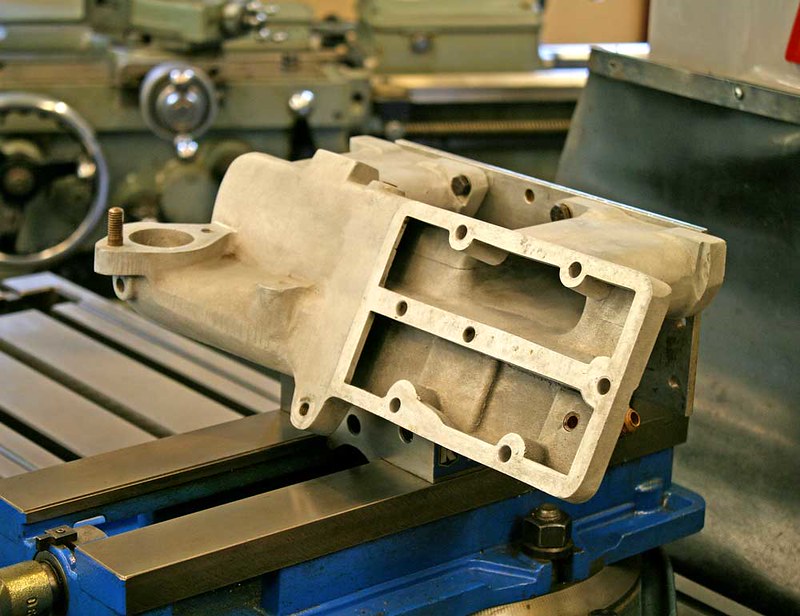

I have been planning to share more photos so it is a good time to start with the intake manifold (above) and (below) the blower housing. The boss used to support the complete blower assembly is seen in the middle of the bottom and is drilled and taped for a 3/8-inch bolt that is screwed down until it rests on the exhaust manifold and then is held in that position w/a lock nut. The front brace is attached to the top aluminum bearing housing bolt and the unused drilled and tapped hole at the right front of the head.  The intake mixture enters in the bottom half of the blower housing seen above through the diamond shaped openings. The compressed mixture exits at the top into the intake manifold. The divider helps to equalize the flow to both the front and rear intake runners. More photos and info soon.

|

|

|

|

|

|

#4 |

|

Member

Last Online: Nov 11th, 2023 13:34

Join Date: Jul 2016

Location: Brattleboro, VT

|

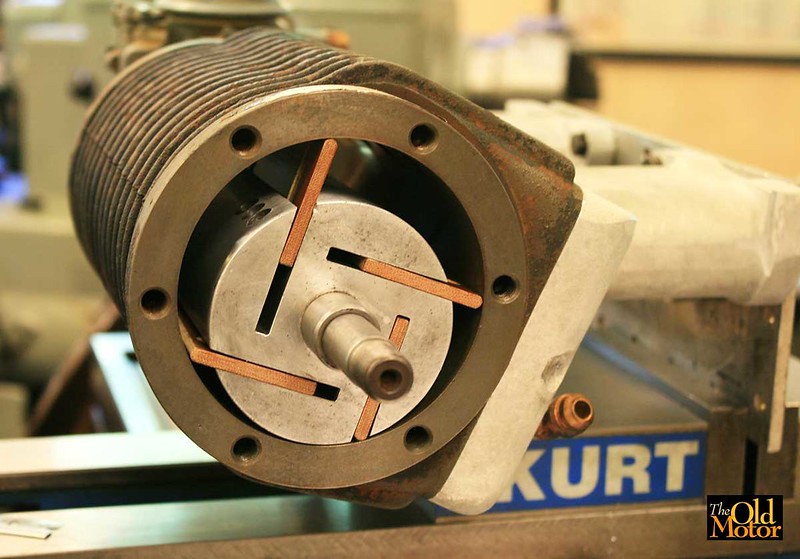

Summer has been super busy here in the shop getting client's vintage racing cars ready to run at events at both Indy and Milwaukee, rebuilding a 1914 Simplex 4-cyl. 600 ci engine and trying to get a little time in here and there on the Volvo. The new micarta vanes for the supercharger are finally finished, and you can see them above in the aluminum rotor, mocked up in about the same location in the housing bore that it rotates in (there is clearance below it). The assembly rotates clockwise, and the right-hand vane is shown about five degrees before it starts to pull in the fuel and air charge from the portion of the aluminum manifold fed by the carburetor at atmospheric pressure. It then compresses it under the rotor; next as it rotates the vane slides out of the rotor slot via centrifugal force, lets the compressed mixture expand until it is forced out of the housing into the intake manifold at a maximum of 5-7 psi.  The intake mixture enters in the bottom half of the blower housing seen above through the diamond shaped openings. The compressed mixture exits through the top half into the intake manifold. The divider helps to equalize the flow to both the front and rear intake runners.  The new vanes above placed in the rotor. They are made of micarda, a tough thermosetting plastic and cloth composite that is the same material used for Volvo "fiber" camshaft gears. The slots assist in collecting the gas, air, and oil mixture to help lubricate the rotor slots and the sides of the vanes.  The housing bore and the rotating assembly will be lubricated by an Ampco "Vapor Lubricator"; this one is a brand new old stock unit. It injects a very fine mist of "Marvel Mystery Oil" or 10 weight oil through a spray nozzle into the carburetor venturi in the amount of about one drop very 4-6 seconds. After passing through the blower, it serves as a top end lube for the intake valve guides, intake valve and seat faces and the cylinder bores and rings. New pressure-sensitive aluminum ID plate below for the front end of the supercharger housing. Next up is to hone the ID of the blower housing on the shop Sunnen precision honing machine, in the same manner as a cylinder bore is done. Then detail everything, get new bearings and seals and reassemble it.

|

|

|

|

|

|

#5 |

|

Steam Driven PC Owner.

Last Online: Mar 4th, 2024 23:50

Join Date: Dec 2004

Location: Not sure.

|

Nice project. There were a couple of companies I have read about that supplied supercharger kits here in the UK back in the 50's and 60's. Interesting to see what the vanes are made of though. I've made parts with a material called Tufnol which seems very similar but had no idea it would be suitable for such an application.

|

|

|

|

|

|

#6 | |

|

Member

Last Online: Nov 11th, 2023 13:34

Join Date: Jul 2016

Location: Brattleboro, VT

|

Quote:

Yes, I looked it up Tufnol is one of the trade names for it. If I ever make a new rotor for it I would like to try Torlon as it works well in rotary vane pumps: http://drakeplastics.com/torlon/ |

|

|

|

|

|

|

#7 | |

|

Member

Last Online: Nov 11th, 2023 13:34

Join Date: Jul 2016

Location: Brattleboro, VT

|

Quote:

Do you have any photos of these other units? I'm always interested in learning more. |

|

|

|

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|