|

|||||||

| Towing and Caravan Topics A forum for all towing/caravanning related topics |

Information

Information

|

|

Balancing caravan brakes - driving me slightly insane.Views : 4052 Replies : 42Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#31 |

|

Premier Member

Last Online: May 3rd, 2024 20:20

Join Date: Feb 2010

Location: North Northumberland

|

If your adjuster is winding almost all the way in before the brakes lock up, it is a sign that either your brake shoes or brake drum (or both) are worn.

In your photos, the shoes do not look to be badly worn, so that would suggest that it is the drum. Many brake drums have a maximum permissible diameter stamped or cast onto them; I am not sure if yours will have or not, but it might be worth looking. One dodge to overcome excessive adjuster travel is to manufacture some spacers that fit between the brake shoe and the wedge of the adjuster - it does not take much; just a mm or two is enough. An alternative is to put a little run of weld down the end of the shoe where it bears onto the adjuster, and dress it up so that it is narrow enough to fit into the slot and flat where it sits on the wedge, again just a mm or so is quite enough: both shoes should be built up more or less the same, but it is not critical that they are exactly equal as the actuator can cope with some discrepancy.

__________________

2018 V90CC D4, 2022 XC40 1940 Matchless G3, 1980 Moto Guzzi T3 Coming soon:- 1947Rover 14 P2 |

|

|

|

| The Following User Says Thank You to 60041 For This Useful Post: |

|

|

#32 |

|

Premier Member

Last Online: Feb 11th, 2023 20:32

Join Date: May 2010

Location: Blyth, Northumberland

|

As 60041 states, those adjusters were common on many British cars. My Triumph Herald and Morris Marina both had them. I still have the Girling adjustment tool for turning the squared end from behind the back plate. I found it helped to dismantle the adjuster whenever I had the brake shoes off. With the shoes off, wind the adjuster as far in as possible. this will push the plungers out almost completely. Remove the plungers then with a pair of pliers on the flats of the cone wind the adjuster completely out of it's housing towards you. Clean everything then re-assemble with brake grease and fully back off the adjuster. Then pack the free space around cone end of the adjuster with some brake grease. Once the shoes and drum are replaced then the adjuster should move freely but you should easily feel it moving from flat to flat as the cone pushes against the return spring pressure of the shoes. Adjust up until the drum is locked then back off by 2 or 3 flats until the drum revolves freely. Sometimes it is necessary to adjust them up again by 1 or 2 flats to achieve an acceptable braking effect, but obviously not so far that the brakes are binding. When satisfied with the adjustment push some grease around the part of the adjuster which is exposed outside the back plate.

Last edited by Ian21401; Jul 20th, 2014 at 00:34. |

|

|

|

| The Following User Says Thank You to Ian21401 For This Useful Post: |

|

|

#33 |

|

Senior Member

Last Online: Apr 24th, 2016 08:02

Join Date: Dec 2011

Location: Dalkarlsberg, Sweden

|

60041: I wondered about this too, the brake shoes appear to have plenty left, and the drums have small concentric lines machined on the inner (contact) surface, which either means that they were manufactured this way and therefore are almost completly un-worn, or that they have both been re-machined at some point, in which case they may now have too large an internal diameter.

If I get no luck at inspection this time, I may try adding some spacers. I know the caravan has done maybe a couple of hundred miles in the last 20 years, before that I have no idea, but it's hard to imagine a scenario where re-dressing of the drum would be necessary. Ian21401: Once I dissasembled the adjusters and realised that they had flats, the adjustment system became clear. The Marina had them? Every system I've been able to find reference to has the star wheel type adjuster. I'm going to be a 60s caravan brake expert by the end of this! I'm considering putting together some sort of guide for rebuilding and asjusting these brakes, because it just doesn't exist. The problem with caravan forums and websites etc is that they are more orientated to making pretty curtains and hunting down melamime plates than providing any actual engineering information.

__________________

I'm not a complete idiot, some parts are missing. Last edited by FullEnglish; Jul 19th, 2014 at 23:46. |

|

|

|

|

|

#34 |

|

I've Been Banned

Last Online: Mar 24th, 2020 22:42

Join Date: Jun 2013

Location: Glasgow

|

Have you checked the shoes match the drums , are they capable of actually contacting it ,if they are only contacting at the apex of the curve you wont get much effect.

|

|

|

|

|

|

#35 | |

|

Senior Member

Last Online: Apr 24th, 2016 08:02

Join Date: Dec 2011

Location: Dalkarlsberg, Sweden

|

Quote:

That's a good suggestion though, I haven't actually laid the shoes inside the drums to check. The brakes will lock the wheels now, so fingers crossed...

__________________

I'm not a complete idiot, some parts are missing. |

|

|

|

|

| The Following User Says Thank You to FullEnglish For This Useful Post: |

|

|

#36 |

|

Premier Member

Last Online: Feb 11th, 2023 20:32

Join Date: May 2010

Location: Blyth, Northumberland

|

Three more queries.

1) You state in your post with the image about bolting up the actuator in any position. Should it be bolted up? Should it be able to "float" to some degree? The Herald and Marina had hydraulic brakes, not cables, so the actuator was a double acting hydraulic piston. It "floated" in a cut out in the back plate, held in place by two opposing "u" shaped sprung steel clips on the outside of the back plate. It's amount of "float" was limited by the size of the cut out in the back plate. The reason for the "float" was so that equal amounts of pressure were applied to each shoe. If one shoe contacted before the other then the actuator was forced back against the other shoe, so equalising the effort on each shoe. 2) The image does not show any "brake shoe retaining pins" These are mushroom headed pins with a "T" shape on the other end. They locate through a hole in the back plate then through a hole on the brake shoe web. They are inserted through the back plate from the back. The mushroom head prevents them passing completely through. At the "T" end, which is now towards you, a small but strong coil spring surrounds the pin, bears onto the web of the shoe and is retained by a cup shaped washer with slot in the centre. Whilst holding the head of the pin against the back plate with a finger of one hand hold the washer in a pair of pliers in the other hand and push it onto the end of the pin against the spring pressure with the slot located so that the "T" end of the pin passes through then turn the washer through 90 degrees so that it is retained by the "T" of the pin. This permits the shoe to move as it should but prevents it "slopping" about inside the drum. 3) The edge of the brake shoes nearest the back plate actually bears against the back plate. There should be slightly raised areas on the back plate. I have found that on very old back plates these raised areas a badly corroded and prevent the brake shoe from moving. Careful use of a file removes the corrosion and smooths their surface then a smear of brake grease to aid shoe movement. |

|

|

|

| The Following User Says Thank You to Ian21401 For This Useful Post: |

|

|

#37 |

|

Premier Member

Last Online: Feb 11th, 2023 20:32

Join Date: May 2010

Location: Blyth, Northumberland

|

Sorry for posting misleading information.

The hydraulic actuator was NOT double acting. It was a single piston which acted on the "leading" brake shoe. The "trailing" shoe was located at the other blank end of the piston housing which also had the hand brake operating lever mounted. When the piston was pushed out by hydraulic pressure it forced the leading shoe against the brake drum. When the shoe contacted the drum the actuator was forced to slide in the opposite direction so forcing the trailing shoe against the brake drum. The mechanical handbrake mechanism operated in the reverse manner. When the handbrake was applied the trailing shoe was forced against the brake drum which forced the actuator to slide in the opposite direction so forcing the leading shoe against the brake drum. Sorry if you know this already. The "leading" shoe is the one which would tend to increase it's pressure on the drum due to the rotation of the drum. The "trailing" shoe is the one which would tend to be pushed away from the drum by the drum rotation. Looking at your image. It appears that it is trailing arm suspension with the shock absorber mounted to the rear of the hub. If this is so I suspect that your image is of the left hand brake and the normal direction of rotation for the drum would be anti-clockwise. This means that in the image the shoe on the right is the leading shoe and the shoe on the left is the trailing shoe. Last edited by Ian21401; Jul 20th, 2014 at 09:23. Reason: Tipping error in the titel but I cnnot corrrrect it nowww. |

|

|

|

| The Following User Says Thank You to Ian21401 For This Useful Post: |

|

|

#38 |

|

Senior Member

Last Online: Apr 24th, 2016 08:02

Join Date: Dec 2011

Location: Dalkarlsberg, Sweden

|

Hi Ian, thanks for posting.

1. The actuator should float (ie be able to travel within the slot in order to sentre the brake shoes). I missed this before as it was stuck (both sides) when I initially dismantled the brakes, and I assumed it was not supposed to move. 2. There aren't any retainer pins, the webs on the brake shoes are off centre (towards the front) so the tension of the springs holds them against the back plate. 3. The shoes move easily against the back plate. Nothing on the caravan has really been badly corroded, mostly stuck together with old grease that has dried and hardened. The actuator on my system only exerts pressure one one shoe, once the first shoe makes contact with the drum, further expansion of the actuator pushes the second shoe against the drum. In the picture, direction of travel (of the van) is to the right and rotation is clockwise. The shock absorber is, for some reason, forward of the hub. There is also no spring. I've just noticed that the wheel on one side appears to be leaning very slightly; I checked everything and the gap between the edge of the drum and the backplate is slightly smaller at the top than at the bottom, so that means that the stub axle has a slight bend in it. Oh joy. I'd better hope that it doesn't fall off now... Ps. Click "go advanced" in the edit dialog box to edit the title!

__________________

I'm not a complete idiot, some parts are missing. Last edited by FullEnglish; Jul 20th, 2014 at 18:20. |

|

|

|

|

|

#39 |

|

Premier Member

Last Online: Feb 11th, 2023 20:32

Join Date: May 2010

Location: Blyth, Northumberland

|

I don't know about caravan hubs etc. but when I converted my Triumph Herald from front drum brakes to disc brakes for rallying I used the front suspension from a crashed Triumph Spitfire. It wasn't obvious until everything was assembled that there was something not quite right about one side. Enquiries with others suggested that the stub axle on that side was bent due to the crash. At that time it was possible to obtain a replacement stub axle and it was a relatively simple job to remove the damaged one and fit the replacement. It may be possible to do that with your van.

I previously owned a 1982 Sprite Musketeer. It didn't have springs fitted. I believe everything was done by the "shock absorber". My running weight was slightly over the maximum for a Musketeer but under the maximum for a Major so I replaced the Musketeer "shock absorbers" with those for a Major and upgraded the tyres. Thanks for the editing tip. |

|

|

|

| The Following User Says Thank You to Ian21401 For This Useful Post: |

|

|

#40 |

|

Senior Member

Last Online: Apr 24th, 2016 08:02

Join Date: Dec 2011

Location: Dalkarlsberg, Sweden

|

The stub axle has a square section on the back side, which is welded to the suspension arm, so it would be theoretically possible to remove this stub axle and weld a new one on, but I think the only realistic chance of repair would be to find a whole new arm and axle from a breaker. I just noticed it yesterday and it freaked me out a bit, I though initially one of the welds on the suspension couplings had cracked. It's only a tiny bit bent, so I'll keep an eye on it and look for a replacement at the same time. It might have been like that for 30 or more years for all I know. I need to re-bush everything and find some new shocks at some point anyway.

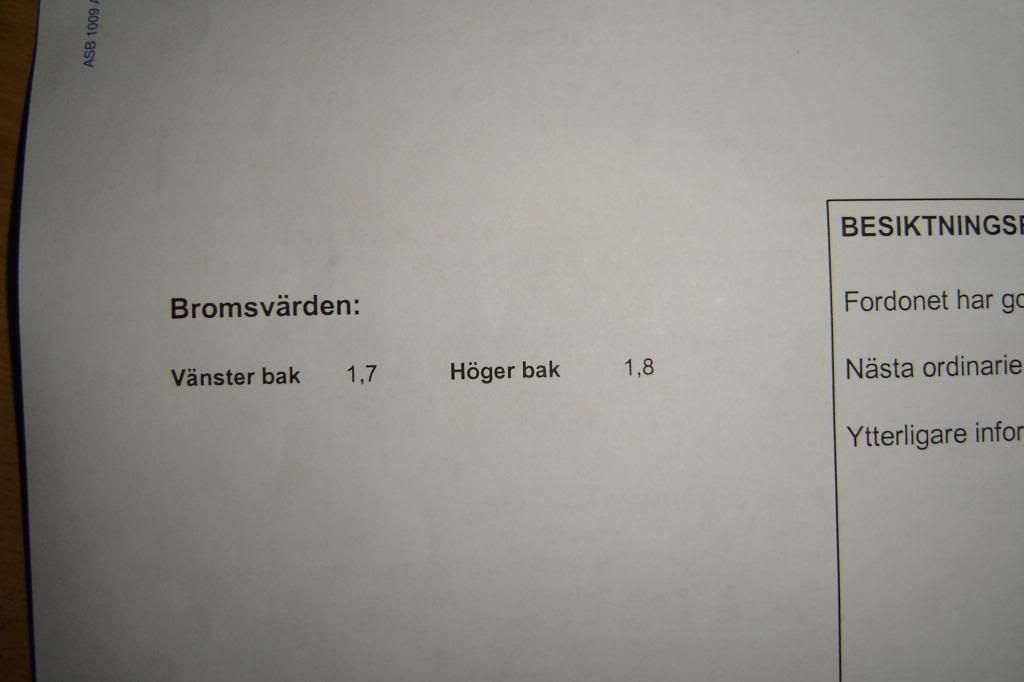

I heard today from my neighbour that there is a workshop in town that has a brake testing machine. I got all excited and took the caravan down there, only to find that they were closed for summer holidays (not unusual for Sweden, rather than everyone fighting over same weeks off and the people with children getting them, the whole company closes for a bit). Since I had the caravan hitched up, I decided to drive on over to the inspection place anyway (about another half an hour away) to see if my latest round of rebuilding had acheived anything. I don't seem to get charged when the caravan fails inspection (I should do, but they seem to have taken pity on me) so nothing to lose really. Anyway, this happened:  IT BLOOMIN* WELL PASSED!!! Here's the quite amazing bit:  Bromsvärden is "brake values". Vänster is "left" and "höger" is right. The brakes on either side are to within 0,1 (of whatever it's measured in, I have no idea what) of being perfectly ballanced. The maximum tollerance allowed is to within 0,5. To say I'm extatically happy is an understatement. I'd like so say a sincere thank you to everyone who has contributed to this thread, whether is be technical insight or just encouragement. This whole saga has been a huge learning curve (it all seems so obvious now!!) Because of the age of the caravan, I don't need to have it re-inspected until 2016. This is bad news, because by then I will have forgotten how to service the brakes... :-D I'm going to have a beer now, too bad it's too warm to fire up the sauna (there's a sauna in the caravan, remember!)

__________________

I'm not a complete idiot, some parts are missing. |

|

|

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|