|

|||||||

| PV, 120 (Amazon), 1800 General Forum for the Volvo PV, 120 and 1800 cars |

Information

Information

|

|

Timing way off the marksViews : 6188 Replies : 33Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#21 |

|

New Member

Last Online: May 25th, 2021 13:18

Join Date: Jul 2011

Location: Maryland

|

Based on the previous recommendation I gave up on the driving collar removal and switched my energy to separating the lobe shaft from the main shaft so I can correct the stuck advance. After many doses of PB blaster, some swearing, and beer I finally pounded them apart with a drift and the lobe shaft clamped in a vise. Now I've got to clean, polish, lube, and lastly reassemble everything.

|

|

|

|

|

|

#22 |

|

New Member

Last Online: May 25th, 2021 13:18

Join Date: Jul 2011

Location: Maryland

|

I got the distributor rebuilt, with working mechanical advance, and re-did the timing. Still in the same spot. I'm going to call it good enough for now and see how it drives when I get it road worthy. Next step before that is redoing the hard brake lines, new master cylinder....

|

|

|

|

|

|

#23 |

|

Premier Member

Last Online: Oct 23rd, 2023 21:39

Join Date: Apr 2007

Location: EXETER

|

I'm bringing this thread up based on some difficulties Old Fart and I recently saw on his B18B where we were unable to get the timing set up anywhere near right. The vacuum advance unit goes right up against the engine block, but is still WAY too far advanced.

Andy - I think you should take the distributor out and look down the hole to check that the drive gears are in correctly. If they are wrong, then the options are to put them in properly (!!), put in a full mechanical advance distributor with no vacuum unit to get in the way or a B20B distributor where the vac unit is on the other side of the body, so won't touch the engine block. It's a bit of a bodge, but should work perfectly well. I have no idea why we were unable to get my dwell meter to work on your engine.

__________________

2006 XC70 D5 Manual 1968 Amazon Estate, B18A + Overdrive 2019 V60 D3 Momentum Pro Manual 1970 Amazon 2-Door 1970 142DL |

|

|

|

|

|

#24 |

|

Master Member

Last Online: May 21st, 2024 14:52

Join Date: Apr 2012

Location: Droitwich

|

Hi Adam,thanks for putting this up.I've done a bodge of my own by removing the vacuum unit from the distributor that was originally on the car and fixing the stator plate in position.This has allowed me to retard the ignition so that I am no longer getting any pinking while driving to work and back and it seems to be running fine.

I'll be going up the motorway tonight,so will see how it behaves up the hills it doesn't usually like. Cheers,Andy. |

|

|

|

|

|

#25 |

|

Senior Member

Last Online: May 19th, 2024 17:17

Join Date: Jan 2014

Location: stranraer

|

Would it be possible to rotate the distributor the other way a quarter of a turn and change the HT lead configuration to suit? Just a thought but without looking at an engine, so please forgive if not possible.

|

|

|

|

|

|

#26 |

|

Premier Member

Last Online: Today 20:13

Join Date: Jul 2007

Location: Connecticut, USA

|

Underdrive; ...nice idea, and it shows you're thinking, but without changing position of Rotor by a similar 90 degrees, high tension would then get directed to the incorrect cylinder...so this is not a valid solution by itself...

...but your concept is valid...let's continue your line of thinking to its desired end...to move the Rotor, move the entire distributor counterclockwise (by first removing Distributor, then lifting the Dist. drive-shaft from Cam, rotating it in the counter-clockwise direction, and replacing it [Crankshaft/Camshaft need to be rotated - in the normal direction of running, while applying just a bit of downforce on the Dist. Drive-shaft- in order to re-engage Drivegear into Oilpump, before reinstalling the Distributor], then repeat timing procedure. Voila! Cheers from Connecticut! |

|

|

|

| The Following User Says Thank You to Ron Kwas For This Useful Post: |

|

|

#27 | |

|

Senior Member

Last Online: Nov 14th, 2016 01:07

Join Date: Feb 2007

Location: essex

|

Quote:

RON you said Underdrive; ...nice idea, and it shows you're thinking, but without changing position of Rotor by a similar 90 degrees, high tension would then get directed to the incorrect cylinder...so this is not a valid solution by itself... ...but your concept is valid...let's continue your line of thinking to its desired end...to move the Rotor, move the entire distributor counter clockwise (by first removing Distributor, then lifting the Dist. drive-shaft from Cam, rotating it in the counter-clockwise direction, and replacing it [Crankshaft/Camshaft need to be rotated - in the normal direction of running, while applying just a bit of down force on the Dist. Drive-shaft- in order to re-engage Drive gear into Oil pump, before reinstalling the Distributor], then repeat timing procedure. Voila! Cheers from Connecticut! in case there is something lost in translation, what overdrive is referring to is to have the rotor arm pointing at number 1 lead, (just as an example) turn the distributor 90* and then remove the spark plug leads from off of the distributor cap and replace them starting with number 1 which aligns with the rotor and proceed with 3, 4 and 2 . (only trying to help) |

|

|

|

|

| The Following User Says Thank You to loon For This Useful Post: |

|

|

#28 |

|

Senior Member

Last Online: May 19th, 2024 17:17

Join Date: Jan 2014

Location: stranraer

|

Thanks Loon, glad to know someone has tried it successfully, it made sense to me in my head but that doesn't always mean it will work. Ron, hope how Loon described it added enough info, I think the method you described would also work but involve a lot more work!

|

|

|

|

|

|

#29 |

|

Premier Member

Last Online: Today 20:13

Join Date: Jul 2007

Location: Connecticut, USA

|

Guys;

I've thought about it some more...and underdrive was absolutely right...I just didn't understand it right...I now agree that rotating Distributor 90 deg in the desired direction such that the vacuum advance/retard housing clears the block, then compensating for that by shifting the HT wires 90 degrees in the opposite direction will have the desired affect...and much simpler and without needing to remove the Dist. drive gear...as a matter of fact, I have actually used this technique myself... Cheers from Connecticut! |

|

|

|

| The Following User Says Thank You to Ron Kwas For This Useful Post: |

|

|

#30 |

|

VOC Member

Last Online: Today 15:34

Join Date: Jul 2006

Location: Chatham

|

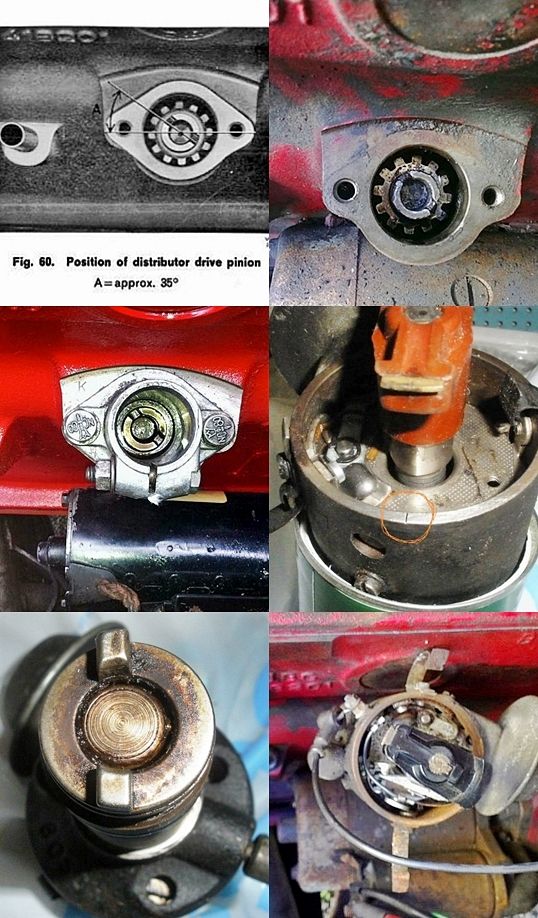

IMHO it's not a case of "yes it will work". It's not "lots more work" to do the job correctly and bring it back to where it should be. 30-60 minutes to complete the job. Pull the gear out with some beefy needle nose pliers and get it set back in the proper position is the only thing that might be a time variable job, as they can be a bit awkward sometimes due to carbonised oil on the shaft. As the gear on the cam and the drive gear are spiral it moves round as you fit it and this is likely your problem. If the engine is in its correct TDC position, remember it can be 180º out, it's just a case of pushing the gear down so it rotates into the correct position as per the book and the pics attached. The slot is offset and matches the dogs on the distributor shaft, again as per the pic, so make sure you have it the right way round. Annoyingly Haynes omits this diagram showing the angle of the slot and hopes you've marked the position of everything. Now days a quick digital pic is a good idea.

|

|

|

|

| The Following 3 Users Say Thank You to Derek UK For This Useful Post: |

|

| Tags |

| ignition, mark, pulley, timing |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|